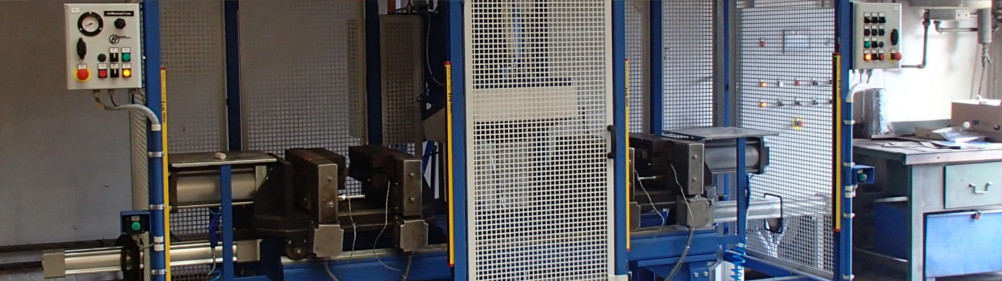

Core shooting and curing machines

Application of the cold production method results in highly efficient manufacturing processes being carried out on single-position core shooting and curing automatic machines. However, the total initial acquisition costs are playing an important role in new technology implementation considerations. Many a time, a budget-priced solution can be found by applying refurbished, upgraded and customized pieces of equipment.

We offer deliveries of upgraded core shooting and curing machines:

- at encouraging prices with a convenient quality-to-price ratio

- featuring a high technical standard and excellent handcrafted quality

- with a high operating reliability having been tested in our own core manufacture

- at favourable servicing conditions

As a rule, the machine upgrade includes the following:

- dismounting the present machine completely, checking its condition, replacement (if necessary) of defective and worn-out parts, complete machine re-assembly, new coatings

- new pneumatic (or hydraulic) distribution system, including addition of new necessary elements

- installation of a new pneumatic-operated sliding gassing plate

- upgrading the machine operating area with a safety guard system including pneumatically operated safety slide doors at the core removal station

- new electric control system of the machine

This upgrade being carried out, the whole core shooting and core curing process will run automatically according to the parameter setting. The control unit enables the machine to be run in several operating modes (basic, with cycle interruption, with repeated mixture shooting, etc.)

Job orders are executed in close cooperation with ELKOSO spol. s r.o.

Thus upgraded machines have been run for several years in our core shop, being subject to a careful examination there.